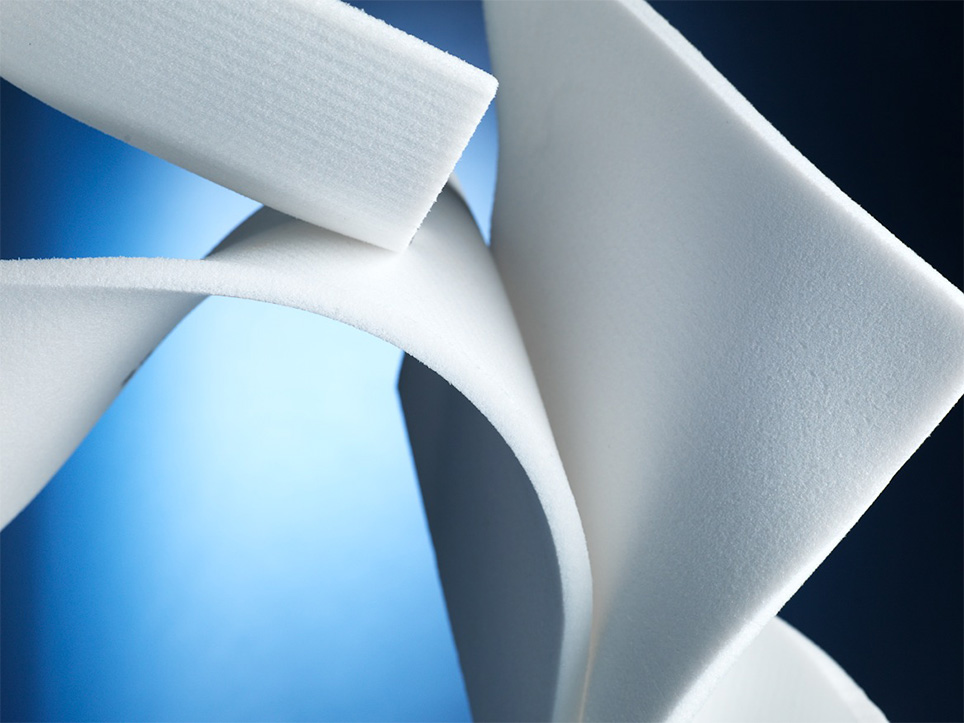

Core Materials

Our product range includes Diab's, which is one of the leading core material producers, Divinycell and ProBalsa, core materials. We have a long and successful cooperation with Diab which started already in the nineties, since when we have been the exclusive distributor of Diab's core materials in the Finnish market. Diab's core materials are used in many different industries, such as aerospace, wind energy, marine and transportation.

Additionally, Diab were pioneers in developing core infusion which has been adopted as the molding process of choice for numerous composite component producers around the world. Diabâ's core infusion process provides a better, faster and more cost-efficient result. We, together with Diab, are happy to advise our customers on the use of core infusion and selection of core materials for different sandwich structures.